40ft Expandable Container House Installation and Precautions

With the rapid popularization of prefabricated houses in the Australian, American, and European markets, 40ft expandable container houses are becoming an ideal choice for small homes, granny flats, holiday homes, and investment projects.

As a professional expandable house manufacturer, UVO utilizes highly prefabricated structural design to enable a 40ft expandable container house to be "quickly transported + efficiently deployed + immediately occupied."

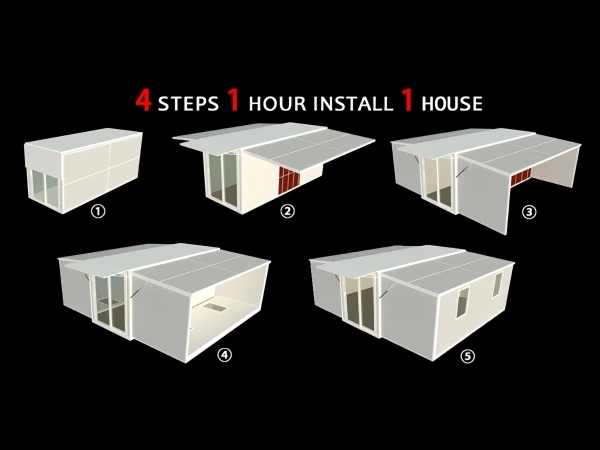

The following content will detail the installation steps and key considerations of a 40ft expandable container house, based on UVO's standard delivery and installation process, and incorporating installation diagrams and videos.

I. Flat-Pack Transportation and Factory Condition

During the manufacturing and transportation phases, the UVO 40ft expandable house utilizes a "fully collapsed" flat-pack transportation mode:

- The overall width and length comply with international container shipping standards.

- Walls, floor, and roof are all folded inwards.

- Doors, windows, electrical wiring, and plumbing are pre-installed at the factory.

- The structural frame is a fully welded galvanized steel structure.

This flat-pack design allows for:

- Significantly reduced international shipping costs.

- Multiple houses can be transported in a single 40HQ container.

- Reduced on-site construction time and labor requirements.

II. Site Preparation and Positioning

Before the house arrives on site, UVO always recommends that clients complete site preparation in advance:

- Site Requirements

- The ground must be level and compacted.

- Concrete strip foundations, point foundations, or steel supports are optional.

- Ensure there is sufficient working space for lifting equipment.

House Positioning

- Use a crane or forklift to accurately place the house onto the foundation.

- Ensure that the load is evenly distributed across all four corners of the house.

- Adjust for levelness to avoid deviations during later assembly.

III. Roof Deployment and Installation

After completing the positioning, the first step is to deploy the roof structure, which is exactly the same as the second step shown in the diagram.

Deployment Method:

- Manual labor + simple mechanical assistance

- The left and right sides of the roof are folded outwards.

- The roof hinges and main frame are pre-installed at the factory.

Design Highlights:

- The roof is a one-piece waterproof structure.

- A complete drainage slope is formed after deployment.

- Waterproof sealing strips and metal edging are pre-installed at the joints.

IV. Floor System Installation

After the roof is secured, the floor system installation phase begins.

Installation Process:

- The folded floor panels are lowered horizontally to both sides.

- The floor panels are connected to the main structure with high-strength bolts.

- The floor is supported by a complete steel beam support system underneath.

Standard Configuration:

- Moisture-resistant sandwich floor structure

- Reserved channels for water and electrical conduits

- Capable of supporting residential-grade loads

V. Wall Deployment and Locking

Once the floor is completed, the side walls begin to unfold outwards. This is the core step in the expandable house's "expansion" process.

Deployment Process:

- Side walls rotate outwards as a whole.

- Automatically aligns with the floor and roof.

- Structural locking is achieved using bolts.

Achievable Effects:

- Interior space instantly expands by nearly 2 times.

- Can create 2-bedroom/3-bedroom/large open-plan living room layouts.

- Door and window positions are precise, requiring no further adjustments.

VI. Finished House Status and Internal System Inspection

Once the wall panels are locked in place, the 40ft expandable container house enters the "finished house status":

- Doors and windows are in place.

- The walls, roof, and floor form a complete enclosure.

- The interior space is ready for immediate construction or use.

The final step of the diagram clearly shows:

A complete, symmetrical, and structurally stable modular house has been completed.

UVO's standard installation efficiency can reach:

4 workers + 10 minutes = 1 complete house structure

After the main structure is installed, only the following steps are required:

- Power connection

- Water supply and drainage system connection

- Commissioning of equipment such as air conditioners and water heaters

Because UVO is 90% pre-assembled at the factory, the on-site work is simply "connection work," not traditional construction.

What should be considered when installing expandable container houses?

The foundation must be level

An uneven foundation will directly affect the accuracy of the unfolding process and the sealing of doors and windows.

Roof first, then floor, then walls

Strictly follow this sequence to avoid structural stress errors.

Check hinges and locking points before unfolding

Ensure they have not become loose during transportation.

Wind conditions must be assessed

It is recommended to postpone unfolding operations in strong wind conditions.

Utilities must be connected by qualified professionals

Ensure compliance with local building and safety regulations (especially Australian standards).

Why choose the UVO 40ft Expandable Container House?

Through highly integrated design and factory-level manufacturing, UVO compresses the traditional building process, which typically takes weeks, into a modular process of "transport + expansion + connection."

Whether you need it for:

- Australian granny flats

- Holiday camps / Airbnb investments

- Temporary or permanent residences

- Commercial or project-based modular buildings

The UVO 40ft expandable container house can be delivered to you at a lower cost, faster speed, and with more controllable quality.