Container Home vs. Prefab Home: Differences and Suitability

What are container homes and prefabricated homes?

Container houses are repurposed living spaces created from retired shipping containers. Originally designed to facilitate efficient cargo transportation by sea and land, their primary considerations were structural strength and cargo protection, rather than comfort and energy efficiency. Prefab homes, on the other hand, are prefabricated in standardized factory-produced components, then transported and assembled on-site. These structures incorporate the functional objectives of modern architecture from the outset.

What is the difference between container houses and prefabricated houses?

Energy-Efficiency Performance: Innate Design Determines Energy Consumption Differences

Container houses are inherently energy-efficient, as their main structures are often constructed of highly conductive steel. In summer, sunlight quickly transfers heat into the interior; in winter, heat rapidly escapes through the metal walls, leading to large temperature fluctuations and requiring extensive air conditioning or heating equipment to maintain a comfortable temperature, increasing energy consumption. Prefab homes prioritize energy efficiency from the outset, utilizing innovative building materials such as lightweight insulated wall panels and high-efficiency insulated roofing materials. These materials effectively prevent heat transfer, minimize heat exchange between indoors and outdoors, and reduce heating and cooling energy consumption.

Insulation and Sealing: Performance Gaps Due to Structure and Construction

Container houses have poor insulation. Original containers have thin walls and lack specialized insulation, leaving heat transfer virtually unimpeded. Furthermore, due to their original design emphasizing ease of loading and unloading, openings like doors and windows lack sealing. Without special treatment after conversion, these gaps can easily form, allowing cold and hot air to seep in, further reducing insulation effectiveness. Prefabricated homes prioritize sealing in their structural design. Factory-based production ensures precise component fabrication and installation, reducing the gaps and leaks associated with traditional construction. High-performance sealing materials and hardware used in doors and windows further enhance overall sealing, preventing cold air infiltration and hot air escape, ensuring stable indoor temperatures.

Improvement Costs: Comparing Retrofits with Innate Advantages

Improving container homes' energy efficiency and insulation requires a series of on-site modifications, including installing insulation, sealing door and window gaps, and applying thermal insulation coatings to metal surfaces. These modifications require significant additional investment, labor, and time, and the results rarely meet professional energy-saving building standards. Prefab houses naturally have good thermal insulation and sealing properties by adopting high-quality energy-saving materials and optimized structural design. They can achieve energy-saving goals without the need for large-scale subsequent renovations, and are more in line with green building and sustainable development requirements.

Who are these two types of homes suitable for?

Container Houses

Short-term project workers, such as construction workers and field surveyors, require temporary accommodation at the project site and will leave upon completion. The portability and quick construction of container homes meet their needs.

Creative Entrepreneurs: Some entrepreneurs in industries like art creation, specialty restaurants, and small retailers like to use the unique design of container homes to create personalized business spaces to attract customers.

Budget-bound Temporary Residents: For those who cannot afford to buy or build a traditional home but need a temporary home, container houses offer a relatively low initial investment (without undergoing a large-scale, high-end renovation).

Prefabr Houses

Families who value comfort and energy efficiency: Prefabricated homes offer excellent insulation, sealing, and energy-saving design, providing a comfortable living environment while reducing energy costs, making them suitable for long-term residents.

Those seeking efficient housing: Prefab homes are prefabricated in factories and assembled on-site, resulting in a short construction period, making them ideal for those who want to move into their new home quickly. Environmentally conscious individuals: Prefab homes are relatively low-pollution during production, and the energy-saving materials used are environmentally friendly, making them popular with those with a strong environmental awareness.

Advantages of UVO Prefab Container Homes

Efficient Construction

UVO prefab container homes utilize a highly prefabricated production model. Numerous component production and partial assembly work is completed ahead of time in the factory, significantly reducing on-site construction time. Compared to traditional construction methods, their construction period can be significantly shortened, sometimes up to one-third. For example, while traditional construction might take months, UVO prefab container homes can be completed in just weeks, enabling rapid deployment. These homes are particularly suitable for projects with tight deadlines, such as temporary offices and emergency housing.

Excellent Energy Saving

UVO prefab container homes offer exceptional energy efficiency. High-quality insulation materials, such as specialized insulating wall panels, effectively block heat transfer and reduce heat exchange between indoor and outdoor spaces. In hot summers, these homes effectively block heat from entering the home, reducing air conditioning and cooling loads. In cold winters, they effectively retain indoor heat, reducing energy consumption for heating equipment. According to actual tests, UVO prefab container homes can reduce energy consumption by 30%-40% compared to conventional container homes under the same conditions, resulting in significant energy cost savings for users over the long term.

Flexible Space

UVO prefab container homes offer exceptional flexibility in spatial design. They can be configured and customized to meet diverse needs. They can serve as independent, small living spaces to accommodate a single person or a small family, or they can be combined to create spacious meeting rooms, large dormitories, commercial spaces, and more. The interior layout is also flexible, allowing for the creation of different functional areas and the adjustment of door and window positions and sizes to meet individual space requirements.

Environmentally Friendly and Sustainable

UVO prefab container homes are highly environmentally friendly. Compared to traditional construction, their production process generates significantly less construction waste, as most work is completed in the factory, simplifying on-site construction and reducing dust, noise, and other pollution. Furthermore, the materials used are highly recyclable, aligning with sustainable development requirements. Moreover, if equipped with environmental protection facilities such as solar panels and rainwater collection systems, it can further achieve energy self-sufficiency and water resource recycling, contributing to environmental protection.

Excellent Examples of Innovative Modular Building Practices

With the growing popularity of green architecture and modular construction, these outstanding design examples, from eco-friendly resorts integrated into nature to precision-engineered low-carbon residences, from subversive commercial complexes to public buildings that embody regional culture, not only transcend conventional perceptions of modular architecture but also demonstrate a perfect balance between industrial aesthetics and practical functionality.

Excellent Container House Design Examples

Rio Perdido Hotel, Costa Rica: This hotel is constructed from 20 shipping containers, cantilevering along the mountainside like vines. During construction, all native trees on the site were preserved, allowing the building to blend seamlessly into the rainforest.

Desert Oasis Container Villa: Located at the junction of the desert and the mountains, this villa is constructed from four 40-foot high-cube shipping containers. Stacked in a single row, the villa features a smart kitchen equipped with all Miller appliances, dual bathrooms, and more. A photovoltaic roof and energy storage batteries form a microgrid system, while rainwater collection and greywater recycling achieve zero emissions, perfectly embodying the ideal blend of luxury and eco-friendliness.

Excellent Prefabricated Housing Design Examples

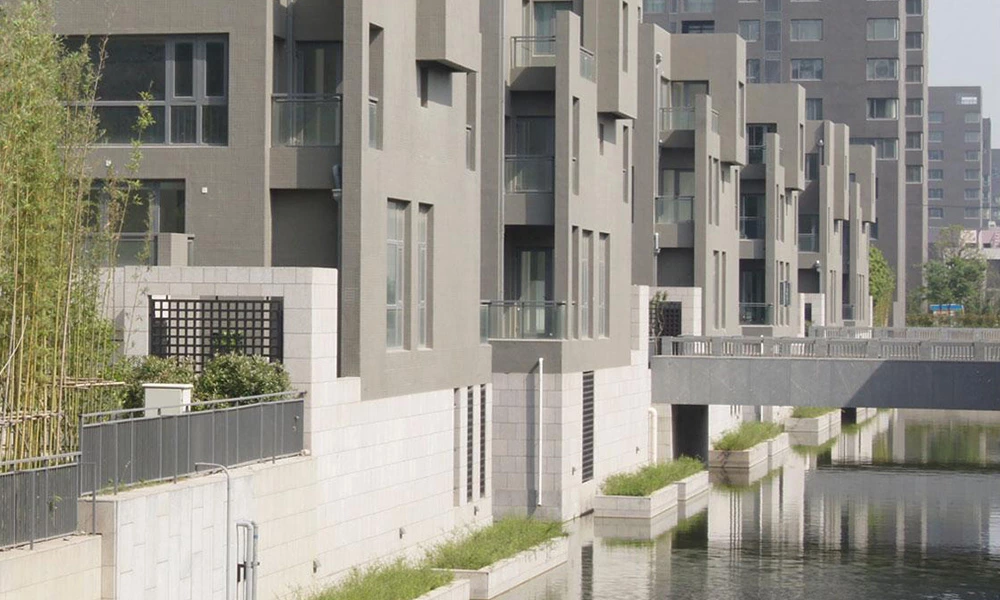

Shanghai Pujiang Town Smart Low-Carbon New Homes: These modular steel structures utilize automotive-grade intelligent manufacturing standards, with a robotic welding production line prefabricating the housing skeleton with 0.2mm precision. Design and completion can be as fast as 30 days, with on-site assembly taking just one day. Each unit also comes with a "digital ID," reducing construction waste by 80% and carbon emissions by 65%.

Minimod Prefabricated Cabins: These cabins feature a wooden frame reinforced with plywood panels on both sides, anchored to the ground with steel anchors or removable concrete blocks. The basic unit accommodates two people, and two or more cabins can be combined to create larger living spaces.